The Rise of UL TPU Cable: A Game-Changer in Modern Connectivity

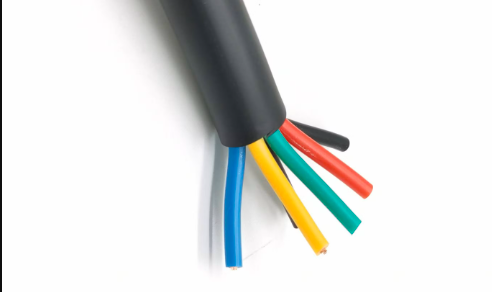

In the ever-evolving world of technology, one often overlooked yet crucial component is the cable. Whether it’s charging a device, powering industrial machines, or transferring data in complex environments, the cable you choose can make or break performance. One standout in this realm is the UL TPU cable—a product that’s rapidly becoming the backbone of modern electrical and data systems due to its superior strength, flexibility, and compliance with strict safety standards.

This article explores the importance, applications, benefits, and future potential of UL TPU cables in today’s tech landscape.

What is a UL TPU Cable?

Let’s break down the terminology.A “UL-listed” cable has been rigorously tested and meets the high safety benchmarks set by UL.

When you combine these attributes, you get a

ul tpu cable a certified, high-performance cable that excels in harsh or demanding environments.

Why TPU?

Thermoplastic Polyurethane is a polymer that bridges the gap between rubber and plastic. It offers the best of both worlds—rubber-like flexibility and plastic-like toughness. This makes TPU an ideal jacketing material for cables that are exposed to physical wear, vibration, and extreme temperatures.

When compared to PVC or rubber-jacketed cables, TPU cables provide:

- Superior abrasion resistance

- High flexibility

- Resistance to oils, greases, and solvents

- Longer life cycles

- Environmental durability (UV, ozone, and moisture)

These characteristics make UL TPU cables highly reliable for industries where performance under pressure is non-negotiable.

Advantages of UL TPU Cables

1. Certified Safety

Safety is non-negotiable in industrial and commercial applications. UL certification ensures that the cable has been tested under the most stringent conditions, providing peace of mind that it won’t overheat, short-circuit, or become a fire hazard.

2. Extreme Flexibility

TPU’s flexibility is a major win for industries with moving parts, robotics, or cable carriers. A UL TPU cable won’t crack or degrade even when bent repeatedly, making it perfect for applications where the cable is constantly in motion.

3. Chemical Resistance

Whether used in laboratories, chemical plants, or automotive shops, TPU cables resist damage from oils, fuels, acids, and solvents—substances that would typically degrade traditional cable jackets.

4. Abrasion and Cut Resistance

Environments like construction sites and industrial automation systems demand cables that can withstand mechanical stress.

5. Environmental Toughness

A UL TPU cable is built to withstand environmental exposure such as sunlight, rain, and extreme temperatures. It maintains integrity in both hot and cold climates, unlike some plastics that become brittle or melt.

Applications of UL TPU Cable

✅ Industrial Automation

Automation systems rely on cables that can endure constant bending and mechanical stress. From sensor wiring to robotic arms, UL TPU cables ensure signal integrity and long-lasting performance.

✅ Medical Devices

Sterile environments require cables that are both flexible and chemically resistant. TPU jackets provide clean surfaces that are easy to disinfect and don’t degrade in medical conditions.

✅ Automotive Industry

Modern vehicles rely heavily on wiring for navigation, control systems, and safety features.

✅ Consumer Electronics

From USB cords to smartphone charging cables, TPU jacketing is increasingly replacing PVC due to its durability and softness, which reduces the risk of cracking or fraying.

✅ Telecommunications

High-speed data cables with TPU jackets resist EMI (electromagnetic interference) and physical damage, making them suitable for rugged telecom environments.

See also: Ghost Kitchen: Redefining the Food & Beverage Industry in the Digital Age

Customization Options

One of the biggest advantages of TPU cables is their adaptability. Manufacturers often offer customized UL TPU cable solutions tailored to specific requirements. Custom options include:

- Color-coding for easy identification

- Shielding for EMI protection

- Coiled or retractable designs

- Multi-conductor configurations

- Fire-retardant or low-smoke formulas

Such flexibility makes it easier to integrate these cables into complex systems without compromising on function or design.

Eco-Friendly Advantage

As sustainability becomes a key concern, TPU scores better than many other materials. TPU is recyclable and often manufactured using cleaner production methods. Many UL TPU cables are RoHS-compliant, meaning they don’t contain hazardous substances like lead or mercury. This makes them suitable for eco-conscious organizations looking to reduce their environmental footprint.

The Future of UL TPU Cables

As industries lean further into automation, electric mobility, and smart devices, the demand for high-performance, reliable cables is expected to rise. The adaptability and strength of UL TPU cables position them as a front-runner in future cable innovations.

We’re also seeing TPU being paired with smart sensor technology for next-generation applications—such as cables that monitor temperature, signal quality, or even mechanical strain in real time. The integration of TPU with data and power transfer will unlock possibilities in IoT, aerospace, and beyond.

Final Thoughts

While often overlooked, the choice of cable is critical in any technological setup. Whether you’re wiring an advanced robotic system or designing next-gen consumer electronics, the cable you use will determine safety, efficiency, and longevity.

It’s more than just a cable—it’s a strategic component in the infrastructure of high-performance systems.

For companies and engineers seeking a future-proof solution, investing in UL TPU cables isn’t just a technical decision—it’s a smart business move.